Supply Chain Management Trends for 2022

After a seismic shift in 2020-21, thanks to COVID-19, supply chain management has had to evolve fast. Many of those new trends will continue in 2022, but newer factors will also emerge.

COVID-19 has been one of the key factors disrupting supply chains around the world, and there is no doubt the pandemic has tested the ingenuity and resilience of supply chains, as they sought to maintain operations. But they have also been a vital lifeline to support the response, keeping essential medical supplies, food, and other key necessities flowing.

We are currently experiencing a transition and evolution of the supply chain with consumer demand increasing, while the drive towards efficiency and agility is more prominent than ever.

One possible surprise: 2022 will not be the year AI, machine learning, automation, blockchain, and the Internet of Things become standard in supply chains. There are far more pressing concerns at hand if companies are to operate at near-normal levels.

Read on to discover what supply chain management teams will need to know in 2022.

Resiliency

A resilient supply chain is defined by its capacity for resistance and recovery. That means having the capability to resist or even avoid the impact of a supply chain disruption – and the ability to quickly recover from a disruption.

During COVID, companies have learned the hard way that the most important thing a supply chain can be is resilient. Raw materials backlogs, capacity limits, and labour shortages continue to pose problems, and a recent Capgemini report found 62 per cent of respondents thought supply chain resiliency would be a key priority post-COVID.

The most resilient and agile supply chains are designed to do more than simply resist and recover. They are built using processes and modern supply chain technologies that allow them to forecast, anticipate and respond quickly to whatever risks or opportunities the future brings.

The study defined a resilient supply chain as having four traits:

- Agility: the ability to pivot fast, including setting up new distribution channels or decreasing or increasing production.

- Diversification: the sourcing of products, transport, and partner companies to move them.

- Contingency planning: the ability to predict demand and prepare for disruptions.

- Visibility: the ability to see what’s happening across all parts of the supply chain.

Resilient supply chains often work more effectively by understanding and leveraging data. When a business has the digital systems in place to analyse and make sense of Big Data, it can lead to significant improvements in supply chain resiliency.

Visibility

Better visibility into complex supply chains will translate into fewer disruptions, increased customer satisfaction, and often lower costs.

Although over 90 per cent of supply chain executives believe visibility is important to success, under a third have true visibility, according to a Forbes study. Success in visibility depends on access to real-time, shared data across every node in a supply chain network, it is important for four reasons.

- Complexity: Modern supply chains are generally global.

- Competitiveness: The supply chain encompasses a significant portion of many companies’ operating budgets, so inefficiency directly impacts the bottom line.

- Customers: Having the right products available at the right locations at the right time is fundamental to customer satisfaction, retention, and acquisition.

- Compliance: International supply chains face tough regulatory requirements, including changing trade agreements (such as BREXIT), procurement rules and governmental tariffs.

As well as saving time, pre-empting issues, and spotting emerging trends, visibility is now a vital part of customer service. Consumers expect 24/7 visibility, and not giving updates on shipments can drive customers away. Even if shipments are delayed, keeping them updated and providing a clear ETA is much better than not.

If we learned anything from an almost overnight shift to remote work, it is that manual processes and paper records are no way to manage a modern supply chain.

Capacity before timeliness

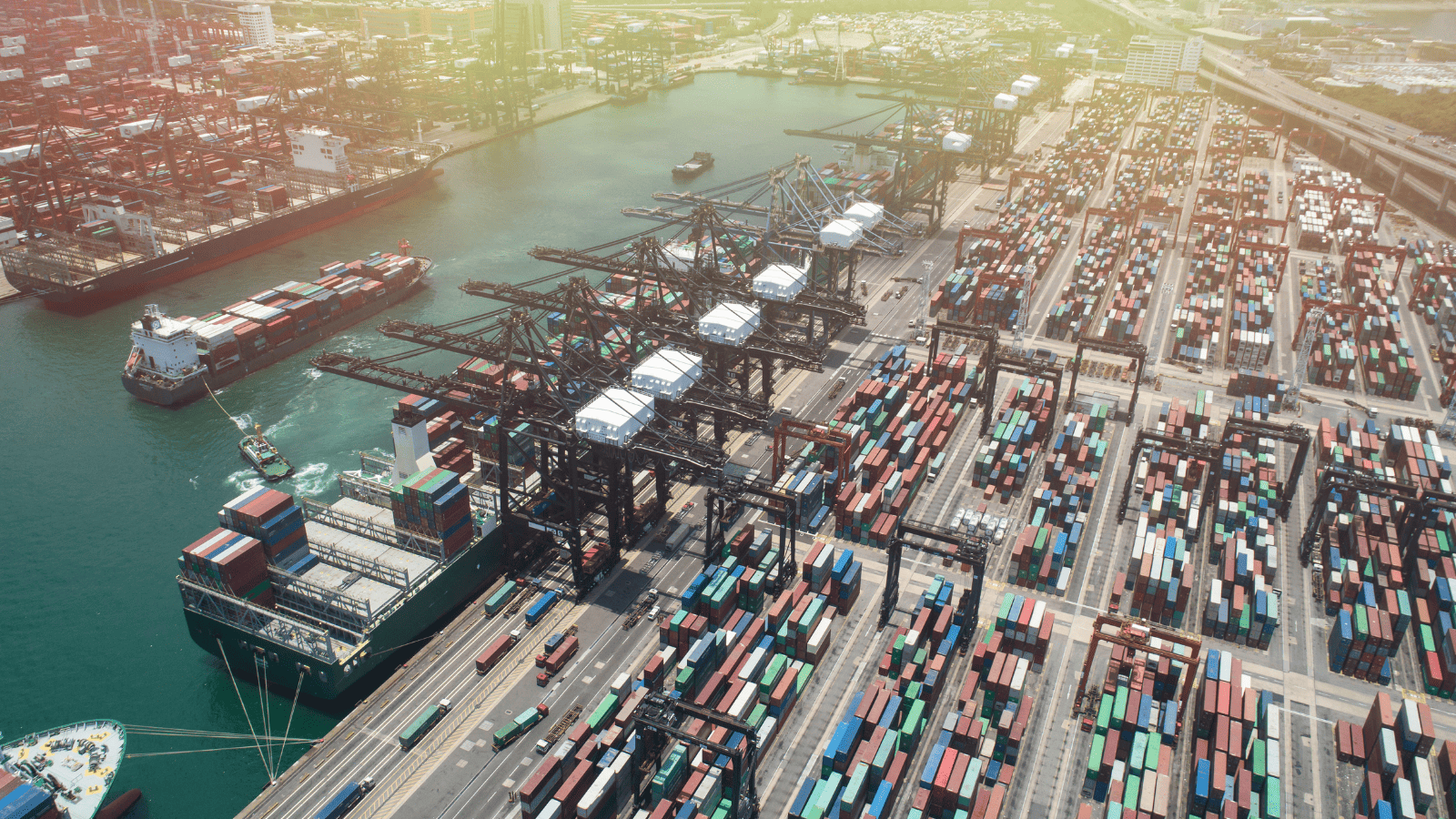

Businesses and their suppliers have faced months of challenges leading to extended order-to-delivery timelines — from port congestion and transportation bottlenecks to raw material shortages to labour constraints at the vendor or manufacturer.

Extended lead times are particularly affecting electronic supplies, which include semiconductors. With lead times at record highs and still accelerating, there has been a seismic change from pre-COVID supply chain models, timeliness was the priority for most supply chain teams, meaning they chose the fastest carriers. Labour shortages and capacity issues now mean there may be no choice, and the priority is to ensure supply chains can keep moving.

Most supply chain management teams will use multiple carriers in 2022 to avoid putting all their eggs in one basket.

Brands have been tackling port congestion challenges by seeking alternative seaports for import or export, or by diverting some shipments to airfreight. Big-box retailers are navigating around longer lead times by accounting for the longer timeline in their supply chain planning.

For automotive and electronics supply chains, the availability of supply to meet elevated demand is a constant concern. Experts predict it could be 2023 before semiconductor suppliers are able to start reducing backlogs. And even when supply is attainable, lead times for electronic components are three times longer than normal.

Price rises

The combination of labour and skill issues, supply shortages, increased demand and transportation costs have led many suppliers to raise prices. It is a convergence of challenges that means supply chain managers face not only longer lead times and potentially higher inventory carrying costs, but also higher materials prices.

Keeping things moving invariably means spending more. Reshoring and nearshoring will be the 2022 trend to try and offset this.

Leaner teams, higher wages

Nine in 10 supply chain leaders say they need to increase hiring to meet peak demand, and 47 per cent aim to attract and retain employees by paying higher salaries or wages, according to a survey from GlobalTranz and Edelman.

Another consequence of the skills shortage is that companies are learning to make do with fewer employees. Well publicised demand includes HGV drivers, warehouse workers and manufacturing personnel, meaning wages for these roles are going up. Some carriers are refusing to ship to or from certain areas until they have the employees to cover them.

Larger quantities, more storage

When supply chains are under stress, the business that already has a warehouse full of supplies is going to emerge as the winner. Overbuying products or materials and storing them in case of shipping backlogs or surges in demand will be a major trend in 2022, with the Capgemini study finding that 39 per cent of businesses plan to shift to this strategy rather than just-in-time manufacturing and sourcing, up from 29 per cent pre-COVID-19.

However, organisations must beware of the risk of over-overbuying, which could leave them over-supply and products they cannot sell.

Sustainability

At the turn of the millennium, sustainability was a relatively fringe idea. Twenty years later it exerts a growing influence over decision making at every level of society. Consumers increasingly want the goods and services they purchase and companies they do business with to be taking visible and accountable steps to reduce the negative impacts of their operations and contribute positively to society. The UK government’s Committee on Climate Change wants the country to be net-zero emissions goal by 2050.

A typical consumer company’s supply chain can account for more than 80 per cent of its greenhouse-gas emissions. As consumer demand shifts further towards sustainability, this is driving more businesses to decrease their environmental footprint.

To achieve a sustainable supply chain, a company must address environmental, social, economic, and legal concerns across its entire supply chain. Taking a holistic approach, reduces waste and environmental footprint, while also improving labour conditions and health and safety — stopping worker exploitation.

A fully sustainable supply chain is one that ensures socially responsible business practices. These practices are not only good for the planet and people who live here, but they also support business growth.

Work with a specialist recruitment partner

Redline - the UK’s most trusted Electronics and High Technology recruitment specialist for professional Contract, Permanent and Executive positions. With four decades of experience in knowledge-led recruitment, Redline is perfectly positioned to offer advice about future-proofing your permanent, contract, or interim needs.

For more information regarding how we can help, please contact us on 01582 450054 or info@redlinegroup.com

Looking for your next role?

If you're searching for your next vacancy, explore our buyer jobs. With roles ranging from customer success manager to production controller and supply chain manager tor purchasing manager, you're sure to find an opportunity that suits your skillset.