Bringing the gap between Engineering and Manufacturing with 2019’s Top Technologies

Advances in technology mean that those working in product design or product development need to ensure that the practices they engage in are kept up to date within the world of design and technology. Individuals in product design need to be sure that they are staying abreast with the latest capabilities and trends: whether that means leveraging new technologies such as digital twin, additive manufacturing or using technology to improve the product development process.

Innovations such as drones, 3D printing, artificial intelligence (AI), and the Internet of Things (IoT) have been steadily maturing along their own trajectories. Insiders, pundits, and surveyed companies say that in 2019, these trends will continue their recent convergence into a tapestry of industrial tools that’s greater than the sum of its parts.

Rachael Dent, Redline’s Manufacturing and Operations Manager discusses 2019’s top trends in product design in engineering and manufacturing.

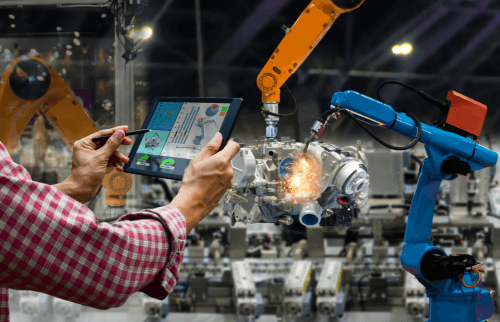

Bridge the gap between Engineering and Manufacturing

Manufacturers are increasingly realising that engineering and manufacturing teams are working in silos to the detriment of the organisation. This leads to the two teams to be disconnected. For example, the engineering team passes information on to the manufacturing team when the designs are finalised and then shares changes to the design when they are implemented. This seems to be a backwards way of working as the manufacturing team waiting for engineering to completely finish their part in the product lifecycle delays the prework that they could be working on in the meantime. Additionally, small changes made by the engineering team can often have a large impact on production. With the use of automated manufacturing process planning, the production engineer or manufacturing engineer could get a head start on what they need to do and automatically see ‘real time’ product information, which would decrease the time-to-market and reduce overall costs associated with rework or remodelling.

Additive Manufacturing

In the past few years, 3D printing technologies have surpassed the limits of prototype production and have achieved the quality and scalability needed for industrial use – which we call “additive manufacturing”. This technology trend has overcome the hype and shows tangible benefits in multiple use cases ranging from ultra-lightweight high-end parts for airplanes to cost-efficient mass customisation of consumer products. Entire industries, like hearing aids and dental implants, have already switched to being almost 100% 3D printed. However, the true disruptive potential of additive manufacturing lies in the digital transformation of the product engineering and manufacturing process. Gone are the design constraints of conventional manufacturing methods – the expensive and time-consuming tooling before even one part can be produced. Gone are the challenges of managing the supply chain and logistics.

The advantages of additive manufacturing became the optimal production technology in a continuously increasing number of situations, despite the high cost for material and production equipment. Low-volume production during the introduction of a new product, replication of hard-to-source spare parts, distributed or local manufacturing in emerging markets… these are just some of the examples where additive manufacturing can yield benefits – even for lower-complexity parts.

Digital Twin and the Digital Thread

The terms ‘digital twin’ and ‘digital thread’ have been around for a while but in 2019, most engineers are going to see both concepts in action every day. By combining the digital definition of a product with the physical experience of the asset in the field, manufacturers will have a complete digital record of a product throughout its entire lifecycle that can be leveraged to improve the product design, ensure that all legal and security regulations and requirements are being met, and to improve efficiency and serviceability.

With a digital thread of information feeding back into product design, design engineers will finally be able to ‘talk’ to their products and answer some of their most burning questions. Whether they’re determining how well the product is functioning in the field or trying to identify which features and functions of the product customers are actually using, the digital thread of information coming back to form a complete digital twin will allow engineers to close the loop in the product lifecycle.

For a full breakdown of the typical Manufacturing & Operations Recruitment handled by Redline, click here.

To find out more about careers in manufacturing or to see our latest job opportunities, please click here or alternatively contact Rachael Dent on 01582 878847 or email RDent@RedlineGroup.Com