Inside Electronics Test Engineering roles

Electronics Test Engineering is about finding the problems long before anyone else knows they exist. A product can look perfect on the bench, but fail in production because of a marginal component, subtle process drift or due to counterfeit and defective electronic components. Electronics Test Engineering jobs exist to catch those problems early and make sure the finished product is something you can stand behind.

Demand for electronics test engineer jobs continues to rise. If you’re considering moving into this career path, read on to learn what Electronics Test Engineering involves, how the role fits into the product lifecycle, and the skills employers value most.

What is Electronics Test Engineering?

Electronics Test Engineering jobs ensure an electronic product meets its requirements. That includes functional behaviour, performance, safety, reliability, and repeatability. In many teams, test engineers also influence the product itself, because good testing highlights design risks early and feeds practical improvements back into the development process.

You’ll see test engineering embedded throughout the full product lifecycle:

- Early development: validating prototypes, exploring edge cases, confirming the electronic circuit behaviours.

- NPI and manufacturing ramp: shaping production test, improving yield, streamlining diagnosis steps.

- Volume production and support: keeping test stable, reducing escapes, spotting trends, supporting corrective action.

What does an Electronics Engineer do day-to-day?

Most Electronics Test Engineering job descriptions combine structured testing, fault-finding, and process improvement. The balance changes depending on whether you’re closer to manufacturing, NPI, R&D, or automation, but the core activities are consistent.

Testing products against specifications

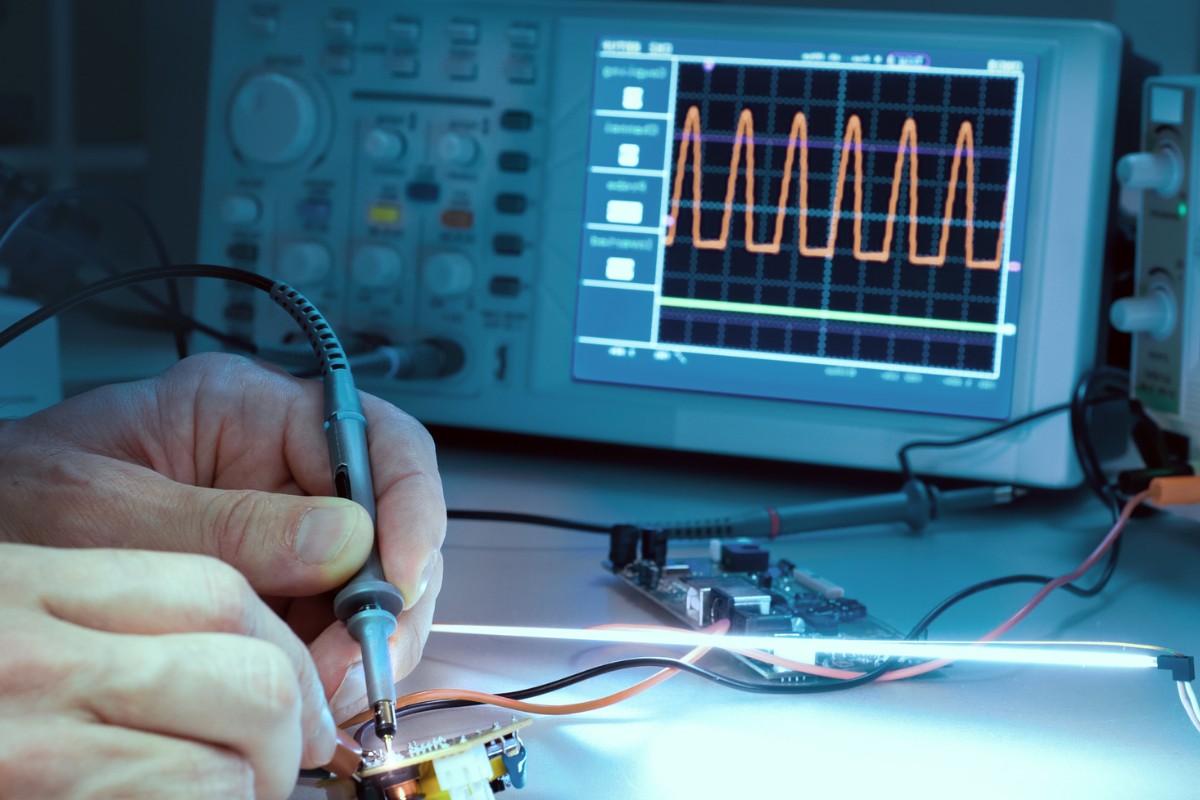

In many test engineering jobs, you’ll be testing items from production in line with regulatory and customer requirements and completing test documentation accurately. That could include analogue, rf and digital testing, confirming expected behaviours, and recording outcomes in a way that’s accurate, traceable and easy to audit.

In manufacturing environments, visual inspection can also be part of the job. Workmanship standards such as IPC guidance are widely used to help define what “acceptable” looks like in electronic assemblies, helping teams assess solder joints, cleanliness, component placement and assembly quality.

Fault finding to component level

When something fails, you’ll work logically through symptoms, schematics, measurements and known-good comparisons to logically isolate the root cause. This is sometimes down to a component, sometimes to a design or process weakness, and sometimes to the test setup itself.

If you enjoy methodical problem-solving and getting clarity from messy real-world signals, you’ll enjoy this part of the role.

Improving test coverage, yield and efficiency

Great test engineers make systems better. That might mean tightening a test plan, enhancing diagnosis steps, reducing test time, or introducing automation.

Key skills employers look for in Electronics Test Engineering

The strongest candidates combine practical electronics knowledge with a steady, methodical way of working.

Technical skills

Most hiring managers look for:

- Confidence in reading schematics and understanding expected circuit behaviour

- Experience testing analogue, digital electronics or rf/microwave devices

- Strong fault-finding skills and the patience to isolate issues properly

- Safe and effective use of lab equipment (oscilloscopes, DMMs, signal generators, logic analysers, RF generators)

- Basic understanding of test coverage and how to design meaningful checks

- Automation exposure where relevant, ATE, modular instrumentation and software (PXI, LabVIEW)

Soft skills

Test engineering is collaborative and time-sensitive. The soft skills that make a real difference include:

- Clear written communication

- Calm problem-solving under pressure when failures affect schedules

- Prioritisation based on risk

- Confidence to evidence-based reasoning

- A steady approach to process and repeatability

Read more: The most in-demand electronics engineer skills

What qualifications and experience help you land test engineer jobs?

For test engineer jobs, employers commonly ask for a degree or HNC/HND in electronic/electrical engineering or a closely related discipline. That said, many teams will favour proven hands-on experience, especially in production and troubleshooting environments.

Experience that tends to translate well into test engineering jobs includes:

- Production test exposure with solid documentation habits

- Bench testing prototypes or assemblies

- Basic automation (e.g. Python, LabVIEW, simple test sequences)

- Collaboration with quality, manufacturing, and design teams

- Work in a regulated or high-reliability environment

Is Electronics Test Engineering right for you?

If you’re considering test engineering jobs, a simple way to sanity-check fit is to ask what makes you tick. Engineers who thrive in Electronics Test Engineering usually:

- Enjoy problem-solving and getting to root cause

- Like practical, hands-on work with clear evidence

- Take satisfaction from preventing failures

- Don’t mind ambiguity, especially in development or automation test

- Like improving systems and processes

Explore Electronics Test Engineering jobs with Redline Group

At Redline Group, we’ve specialised in electronics and technology recruitment since the early 1980s. We support hiring across the full product lifecycle, from early concept and R&D through integration, test, support, and manufacture building world class teams. Whether you’re an experienced test engineer or exploring a career move, our consultants can guide you towards roles that fit your skills and experience.

If you’re ready to explore opportunities, view our wider Electronics Jobs and Electronic Test Engineer jobs today.