Augmented Reality saved COVID patients – now it could save manufacturers

You may have read that in the past year, manufacturers from industries as wide-ranging as automotive and aircraft to Formula 1 teams stepped up to respond to produce nearly 14,000 new ventilators for patients hospitalised with COVID-19. This massive and life-saving effort was a true testament to the power of ordinary people working together for the common good – but what you might not know is that they also had the power of promising new technology on their side.

Augmented Reality (AR) systems allowed the manufacturing engineers and assembly technicians to learn about the existing ventilators, designed by Smiths Group and Penlon, and develop the manufacturing process even when they could not collaborate in person. While the companies involved are experienced in complex and precision engineering manufacture, none of the consortia businesses had ever built a ventilator before – medical technology manufacturing is a very specialised field, and even these ventilators, designed for rapid production, each took 24 hours to build.

Both Smiths Medical and Penlon used AR techniques to capture step-by-step procedures, processes, and best practices as they built a ventilator allowing documents, images, and insights to be generated into a ‘virtual guide’ with reusable process documents, job aids, and training materials which could be accessed by the consortia members working on the Ventilator Challenge UK.

This use of AR technology has already started to accelerate with other companies such as major pharma company Watson-Marlow Fluid Technology Group, who have recently invested in AR to support the transfer of production and assembly techniques to other global manufacturing sites thus allowing for increased safety and improved knowledge transfer without the need for employees to travel - especially critical in COVID-19 times.

Boeing has used augmented reality to provide technicians with instructions for airplane wiring schematics in their field of view, allowing them to be hands-free. This reduces wiring production time by 25%, increases productivity by 40%, and reduces error rates.

The ventilator challenge was not just a critically important project where lives hung in the balance-it was also an opportunity to demonstrate AR and its potential increase in use. The forced COVID need for remote communication and collaboration is believed to have driven the increase of digital transformation in manufacturing by two to three years.

The idea is that AR’s line-of-sight visualisation can guide front-line workers. Compared to the ‘mental mapping’ they otherwise do with 2D instructions, line-of-sight support boosts productivity.

This potential use of AR is not a moment too soon. The engineering industry is currently on the verge of losing traditional engineering skills forever, it’s getting harder to retain institutional knowledge with an ageing workforce due to retire and the lack of trainees to replace them. This becomes an expensive problem for industrial enterprises. Augment Reality solutions may offer a partial solution to some of those problems.

Just like in the Ventilator Challenge UK, AR can create a cloud-based library of recordings of senior engineers and technicians demonstrating their skills for generations to come. The instructions can be accessed at the actual point of use, which has been shown to speed up learning. At Volvo, AR is cutting quality operators’ training from five weeks to less than two.

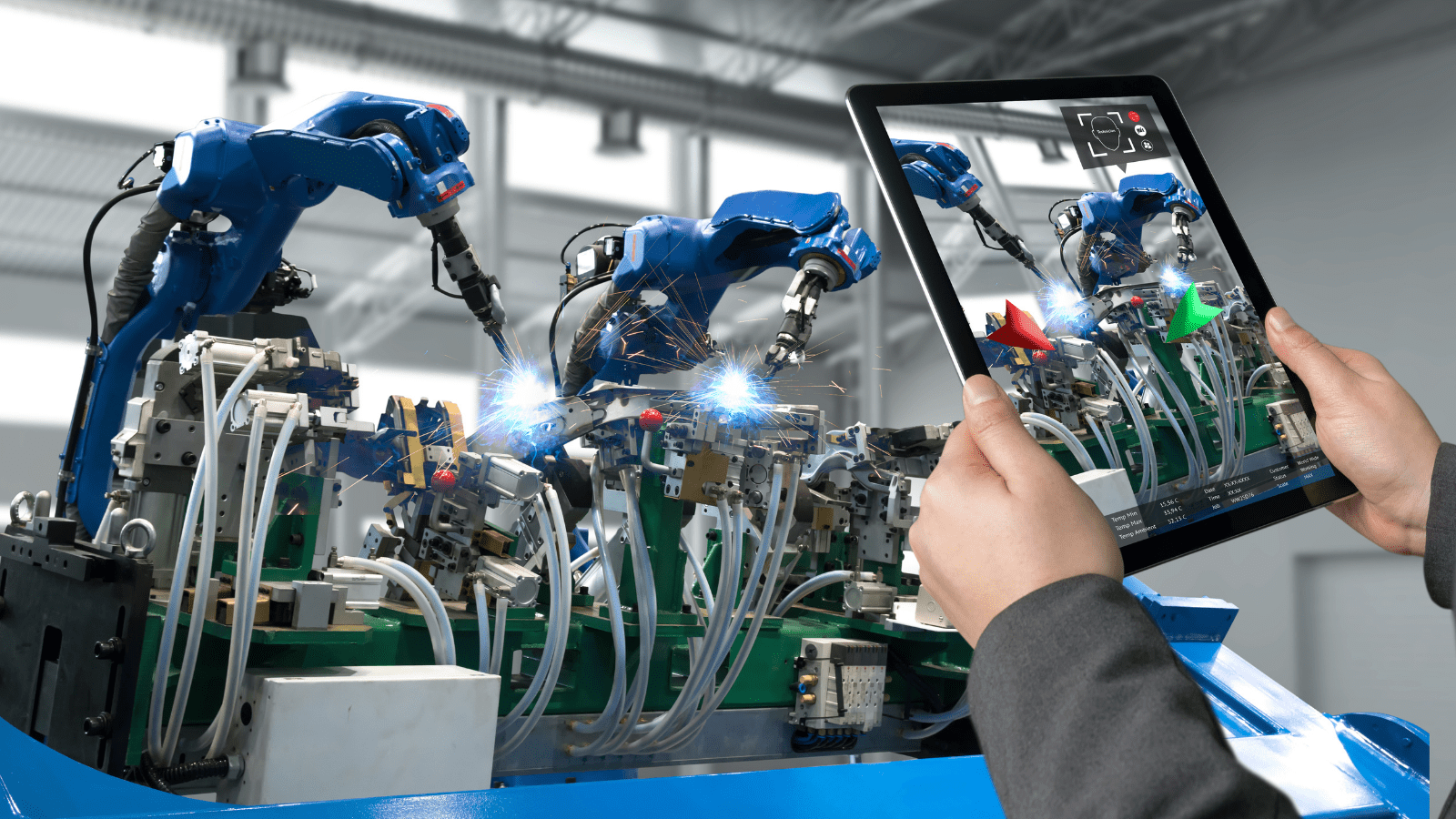

Importantly, these instructions can be delivered at the point of use, which has also been proven to speed up learning. A digital layer is superimposed on the physical world, integrating the physical, real environment with virtual details to enhance or “augment” the real-world experience

New starters will be able to access them on mobile or tablet, or through smart glasses or head-mounted displays for a hands-on experience. Even traditional heavy industries such as steelmaking have expressing interest in this type of technology.

Recent studies showed that seventy-one percent of early achievers believe that immersive technologies will have a substantial impact on organisations and industry soon. Yet most companies are in the exploratory phase of proofs of concept and pilots.

The biggest growth is still on the horizon with the use of AR in the context of Industry 4.0 or digital manufacturing, facilitating production, quality, and safety. Once 5G is commonly available in manufacturing environments with the ability to transmit to multiple sensors and devices the AR training environment could become seamless.

A primer on Industry 4.0 published in Forbes describes it as enhancing existing systems with “smart and autonomous systems fueled by data and machine learning.”

Augmented reality is one of the core technologies, and over the next five years, AR is projected to achieve a 20 percent increase in industry adoption—the highest of all Industry 4.0 technologies.

With AR applications for IIoT/ IoT data visualisation, employees will simply hold a mobile camera over a specific node on a machine to reveal real-time data on its operations, such as temperature, electricity flow, and power levels—thus increasing work efficiency and making a diagnosis of problems easier. With AR, employees can also remotely collaborate with experts for any troubleshooting guidance.

Baker Hughes, a GE company, is using the technology to extract data from sensors of live turbines, to construct a digital replica or digital twin. The customer can then run tests on the digital twin to find the most efficient and e?ective way to operate their production. Instead of testing on real equipment, which costs millions of dollars to build and operate, they can run simulations on the digital twin which then informs how to optimise the work?ow. When data is presented in 3D, rather than abstract forms such as charts and graphs, it is easier to create actionable insight and make decisions.

However, some barriers to adoption remain, especially for SMEs. Cost is one, but many businesses also lack a clear understanding of the tangible business benefits of AR/VR or lack inhouse expertise – something the nascent industry is working hard to remedy.

Immersive technology has come a long way in a short time and will continue to evolve. For organisations Augmented Reality can potentially bridge gaps by improving learning engagement and retention in real-time while delivering real business benefits.

Redline Group is a niche recruitment Consultancy specialising in professional Contract & Permanent Recruitment and Executive Search within High-Technology, Electronics and Engineering sectors since 1982. Our expertise lies in enabling high-technology and engineering companies to build world-class teams through knowledge-led recruitment.

For more information regarding how we can help your business grow, contact Redline Group on 01582 450054 or email info@redlinegroup.com.