How can we solve the semiconductor shortage?

The chips, as they say, are down.

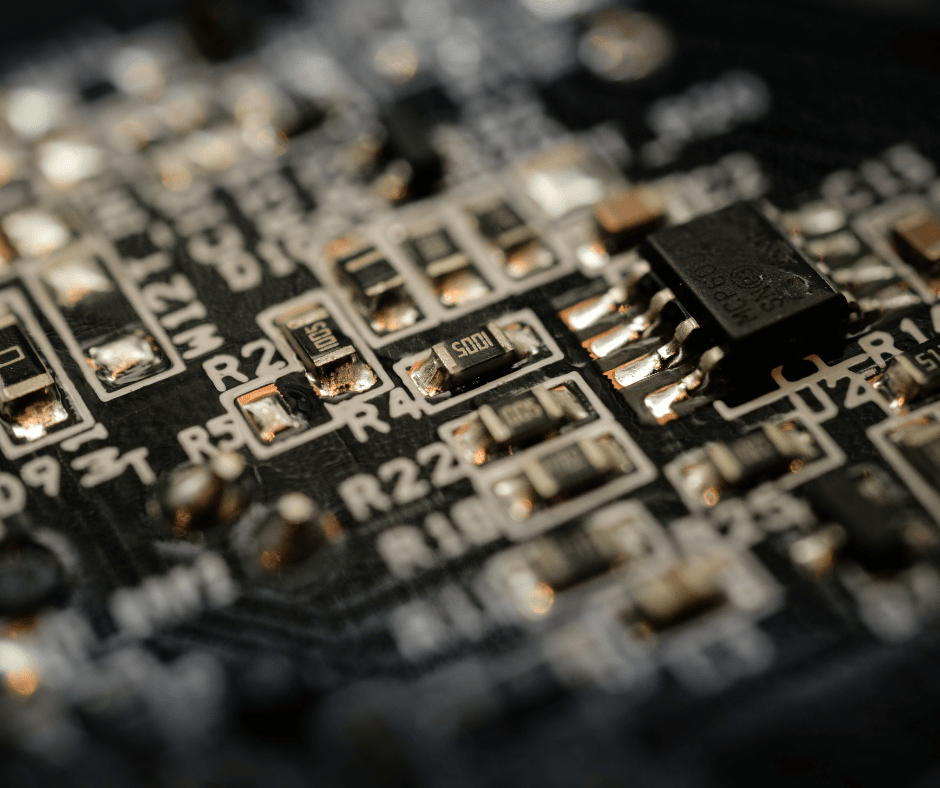

A global shortage of the semiconductors that power most digital tech is keeping the future on hold for many consumers, delaying the release of new gadgets and slowing down the delivery of the next generation of AI software. As more and more everyday items (watches, fridges, cars) become ‘smart’, the demand for electronic hardware to run their features rises rapidly, and right now – partly due to (everybody says it together) pandemic-related disruptions – supply is not keeping up.

Demand for semiconductors of every size and power has risen consistently over the last several years and, until the present manufacturing crisis, supply has mostly been able to keep up. These shortages may get worse before it gets better. Analysts predict supply chain issues might slightly ease in the second half of the year, but structural problems and the increasing levels of demand will make predictions inaccurate until 2023.

The automotive sector has been hit hard, according to GlobalData, the global light-vehicle production amounted to 79.9 million units in 2021, 4 million below demand. Worldwide, supply chains are still recovering or have been forced to downsize permanently. The COVID-19 pandemic has exposed a weakness in the eco-system within both Europe and other regions of the world.

So, what can be done? That is the question challenging some of the technology industry’s top innovators right now.

National governments and combined Continents are all publishing policies and directives. This week the European Union published the European Chips Act.

Despite the strength in semiconductor innovation within Europe, it has an overall global semiconductor production market share of less than 10% and is heavily dependent on third-country suppliers, mainly in Asia. In case of severe disruption of the global supply chain, Europe's chips' reserves in some industrial sectors (e.g., automotive or healthcare devices) could run out in a few weeks, bringing many European industries to a standstill.

The Chips Act is an opportunity for Europe to act jointly across all Member States, to the benefit of the whole of Europe. However, the current chips shortage is a systematic issue with no quick fix. This initiative will pool together €11 billion of public investments up to 2030 from the Union and the Member States and will leverage considerable private investments.

But these policies and other investments from the likes of TSMC - up to $44 Billion investment in 2022, Intel investing more than $20 billion to build two new factories - will not solve the problem quickly.

Semiconductor companies were investing in fab capability before the pandemic, and they have stepped up since the shortage began to be felt initially in the consumer electronics and mobile phone markets. But many aspects of the process remain stressed, from delivering materials, the TAM in global wafer processing capability to assembling the devices. In areas where vaccine access was initially more difficult for instance, COVID safety measures meant factories could not have as many workers onsite.

Many semiconductor suppliers are trying alternatives to increase capacity. This includes increasing the number of chips per silicon wafer via improving yields, a measure that could marginally improve manufacturing capacity during the supply chain crunch, but experts say it won’t be enough. To fully meet demand, semiconductor chip production would need to double or triple.

Another approach that shows more promise is the use of manufacturing infrastructure that is no longer state of the art to produce devices that are. Engineers at some tech giants are even designing gadgets that can run up-to-date software on semiconductors from prior generations, while others are devising ways to use outdated semiconductor equipment to produce the latest semiconductor designs.

All these solutions are serviceable in the short term, but a better shot at closing the gap may lie in software solutions, not hardware. Updates are faster to deploy and could make many industry goals like AI-powered cameras and face recognition a reality without much dependency on new electronic and semiconductor biased hardware. While in the past electronic hardware efficiency placed major limitations on what software could do, advances in smart compression and compilation have the potential to open major possibilities.

Smart compression and compilation in machine learning mean much more than keeping download sizes low. To reduce a working model’s size and power demands, engineers are looking at which parts of the model are necessary for its outcomes and “prune” layers, filters or channels that can be cut without unduly cutting accuracy. Another key factor is “quantization,” finding places where computation cycles can be saved by reducing precision without affecting the outcome.

The compilation then maps the compressed model’s high-level operations to the low-level ones supported by the architecture of a chip.

But finding the best method for these crucial processes is far from simple. Intricate machine models must be compressed and compiled with a view to the target environment, which could be a smartphone, a scientific instrument, or a home automation device, each running different operating systems.

This kind of tailoring to the specific architecture where a model is intended to run can create huge efficiency gains. Also, existing mainstream devices can give engineers and developers the real-time experience with AI applications they have been seeking. Everything from natural language models to selfie filters can run natively faster than they might on specialised hardware, demanding nothing of the user but a normal app install. That means developers could deploy the next generation of technology, AI, etc. without the need for multibillion-dollar infrastructure plays.

The semiconductor shortage looks set to remain an issue until at least 2023/24, but that does not mean an AI-powered future has to be put on hold. Software-based solutions have made a huge contribution to current advancements in machine learning, and they have the potential to take us much further without all the necessary hardware.

For more information, from a trusted partner with over 35+ years of experience in knowledge-led recruitment in the Electronics, Semiconductor and High Technology arena, please contact us on 01582 450054 or email info@RedlineGroup.com.